FBA 2500 / 4

Make an inquiry

Description

automatic screwing of metal mounts on side-hung, pivot-hung and french casement windows

Highlights

- Can be used for any metal mount and profile types

- Simultaneous assembly of three sashes

- French casement sashes can be screwed automatically

- Automatic restrictor and closing device

- User-friendly thanks to visual display of the metal mounts

- Four screwing units are active simultaneously

- Controlled and monitored screw feed

- A number of different screw lengths can be used

- Process-reliable operation for industrial screwing of metal mounts

- Automatic outward transport

Options

- Automatic logistics system for sash management

- Accurate drilling of the corner hinges

- Screw feed devices for additional screw lengths

- French encasement sashes

- Extension of rebate dimension is possible

- Worktable for sash assembly BMT 2500

- Sash mount shelf FBR 40 / FBR 41

- Barcode scanner

- Wood design

- Aluminium design

What else you should know

Highest adaptability

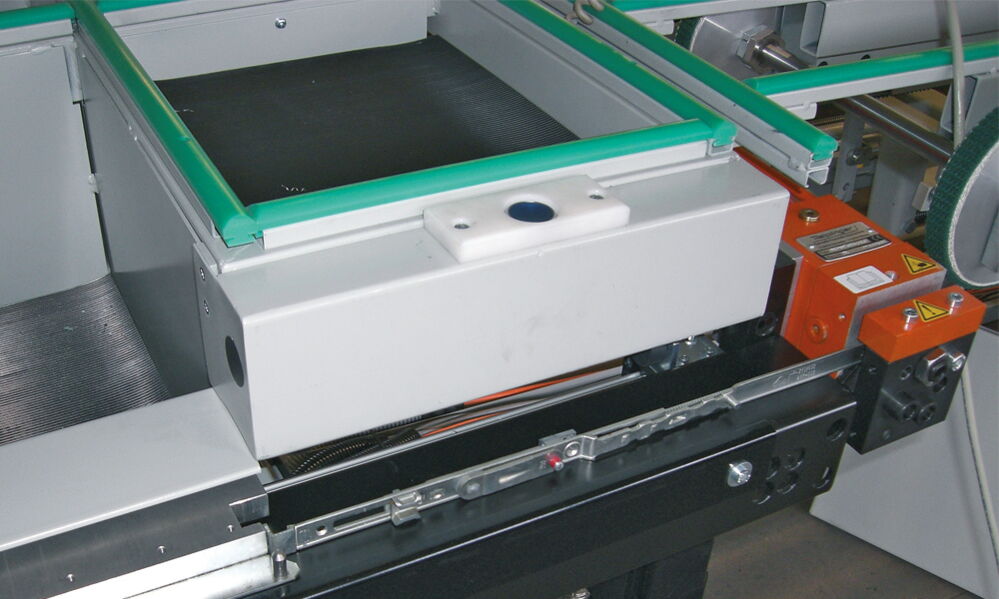

The unit can be used for any metal mount and profile types thus offering you maximum leeway and flexibility (pictured: electronic stop and automatic punch).

Highest quality assurance

The automatic fault detection during the screwing process will detect any faulty elements that do not meet the quality standard. Optionally, you can discharge these elements via a roller conveyor.

Well-conceived solutions

Tilt restrictors that must remain open during screwing are closed automatically during stacking. This ensures a smooth production process for different metal mount variants.