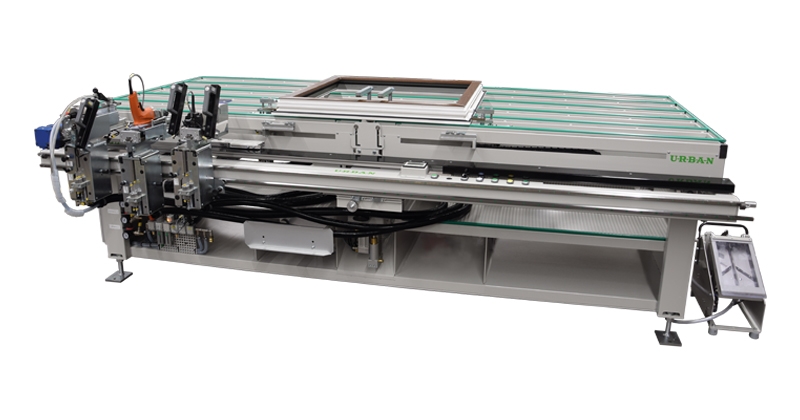

FAS 320-2F

Make an inquiry

Description

efficient assembly and screwing of mounts

Highlights

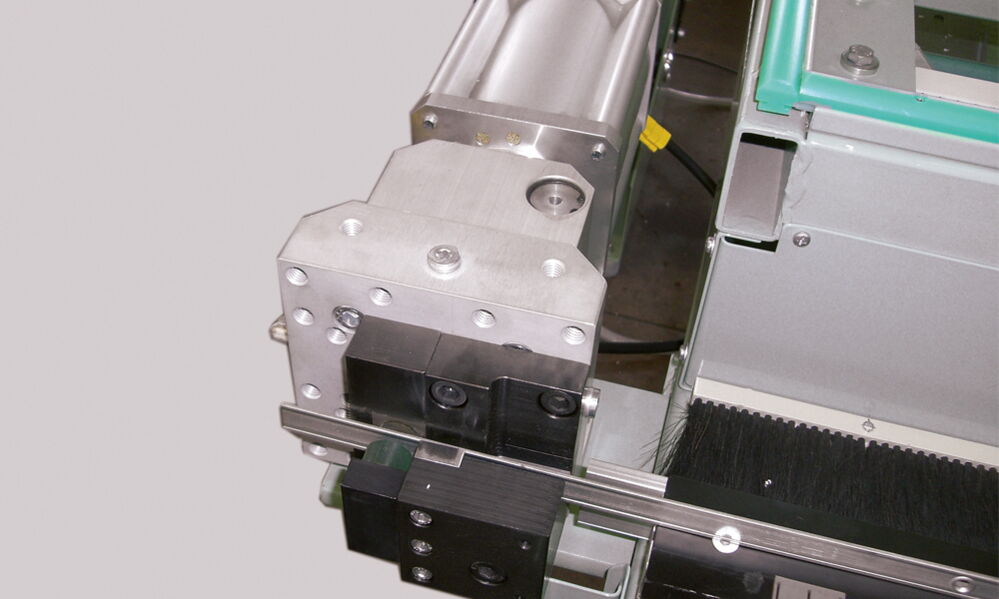

- Automatic centring and clamping unit

- Outer scanning of the sash (rebate dimension)

- Pneumatic table inclination from 0° - 15°

- Profile-protecting sliding or felt strips

- Quick and accurate positioning of the screwing unit

- Different screwing heights can be adjusted

- Automatic screw feed

- Electronic table control

- Two heavy-duty guide rails for version 2F

Options

- Handle drilling unit

- Lock case milling unit

- Glazing bead measuring system with wireless / barcode printer

- Barcode laser scanner for screwing unit

- Stainless steel support

- Punch preparation or punch

- Corner hinge drilling unit optionally with 2-spindle drill head

- Assembly system for central and constant handle seat

- Mounting shelf with 33 or 41 compartments

- Wood design

- Aluminium design

What else you should know

BS-320 Metal mount punch

with open cutting tool for straight cutting; different punches, e.g. hole punch or special punches, can also be implemented.

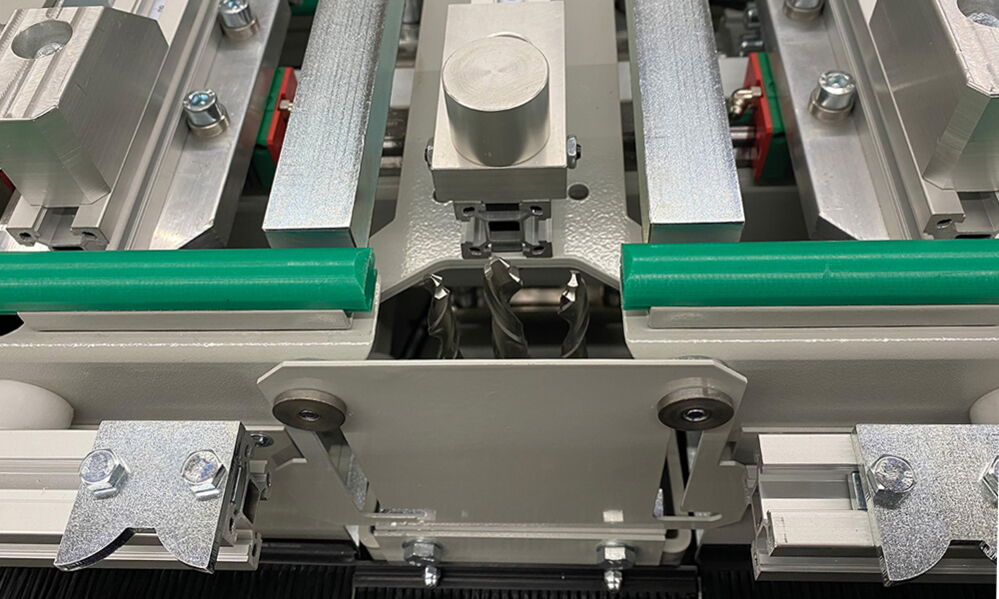

FE-320 Milling unit

mobile, incl. pneumatic height-adjustment with four-way turret stop at the top and at the bottom, manual depth adjustment, two-hand operation and stop for lock case milling

GOB-320 Handle drilling unit

stationary installation with hydro-pneumatic drill feed clamping unit and three-spindle drill head